The constant challenge for the KFA,the leader of the Smart Factory, continues.

Smart Factory

Smart Factory

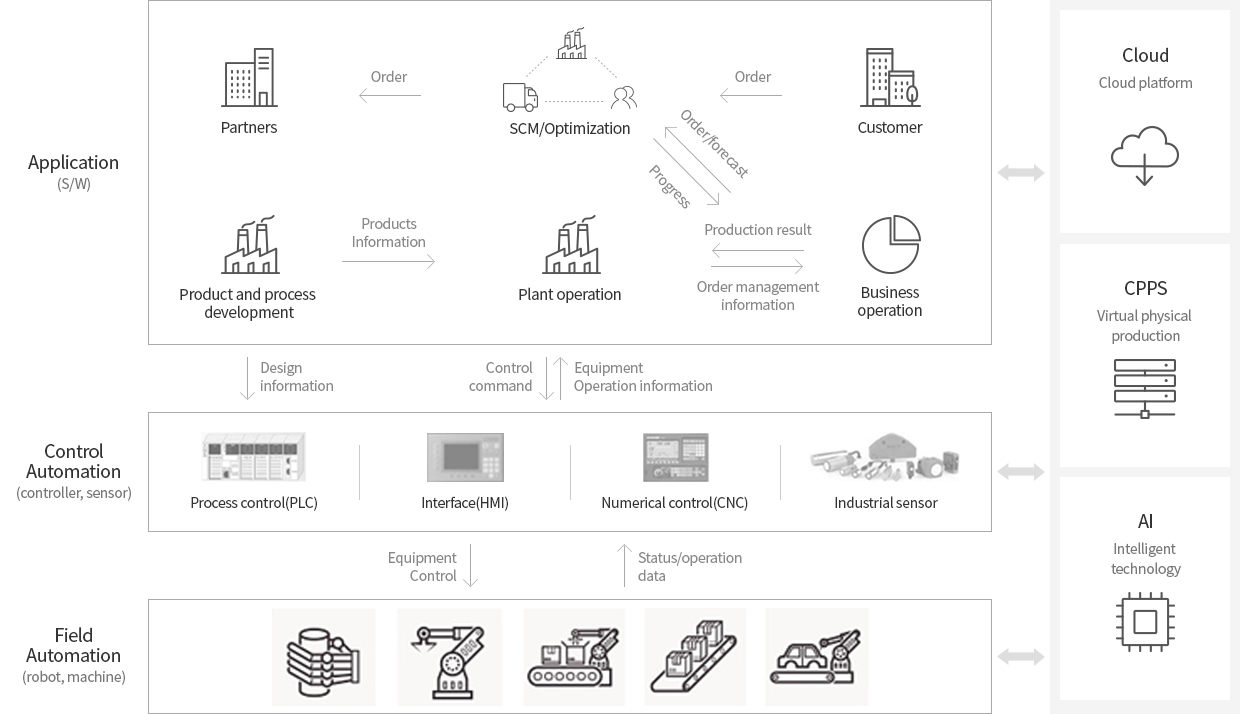

Smart Factory includes everything from product development to mass production, market demand forecasting, from parent company orders to finished goods shipment, and vertically includes all areas of field automation, control automation and application systems.

We, Korea FA System provide real-time aggregation, real-time material flow, lot-tracking, quality analysis, real-time monitoring, automatic equipment control, and interworking with other systems. Furthermore, we are providing an integrated system aimed at autonomous plant operation through intelligent facilities and systems that judge themselves by connecting equipment, materials, and each systems to a wired/wireless network.

Consulting

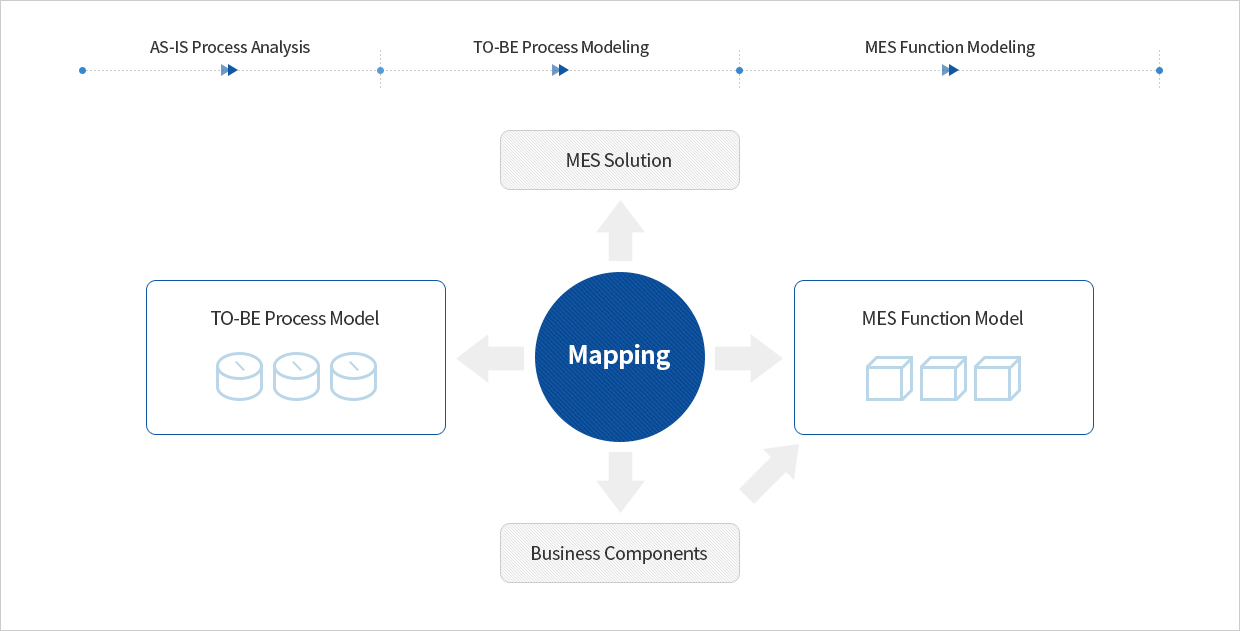

We supplies verified and optimized consulting services based on the accumulated know-how and structured experience to achieve the best competitive power to the customers.

-

- MES

-

- Extracts the AS-IS process issue and presents the improvement target

- Presents optimal MES deployment plan

- Establish system for continuous process monitoring and improvement/management

- MES Diagnosis and deriving improvement direction

- AS-IS process diagnosis, analysis and modeling

- Establish change management system

-

- Solution

-

- Supplies the most suitable solution as per production environment (Plan/Production/Process/Quality/Equipment management and Process logistics, etc.)

- Supplies Solution

-

- Sytem Construction/ Operation

-

- Supply the most suitable system to implement the standardized process

- User Training & Technical Support

- System Design/Development/Installation/Try-Out

- System Operation/Maintenance

Supply MES Solution

The automation of the production line is changed from automation for single machine to FMS(Flexible Manufacturing System), and it is integrated with computer. The MES is contributed to improve the productivity and quality by collecting and analyzing the information in the production activities and providing the most suitable functional solutions (Plan/Production/Process/Quality/Equipment management and Process logistics, etc.)

KFA Function Model

- Planning

Control - Order

Mgmt. - Result

Mgmt. - Progress

Mgmt. - Quality

Mgmt. - Process

Mgmt. - Equipment

Mgmt. - Logistics

Mgmt. - Status

Mgmt.

- Others

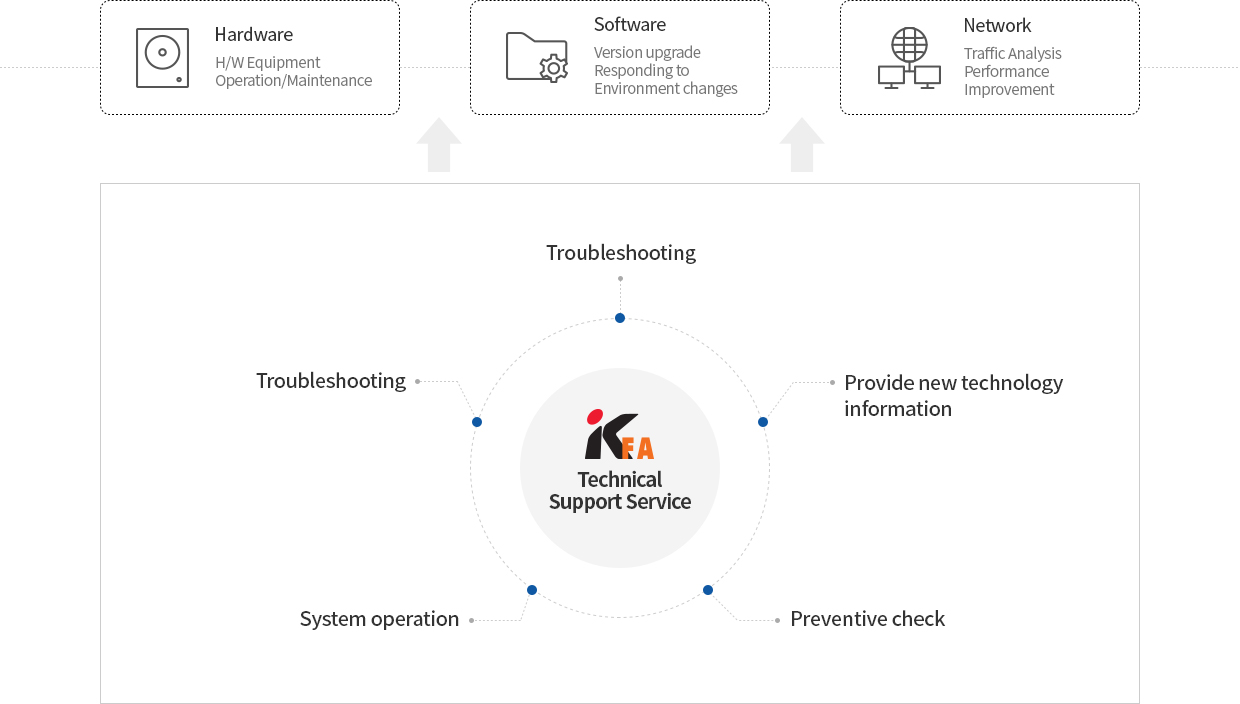

Operation/Maintenance

Unfortunately, sometimes the system is not available because of unexpected problems and errors. The maintenance of the MES means specialized technical services for the unexpected problems to prevent the loss of significant information, and reduce the cost by immediate maintenance.

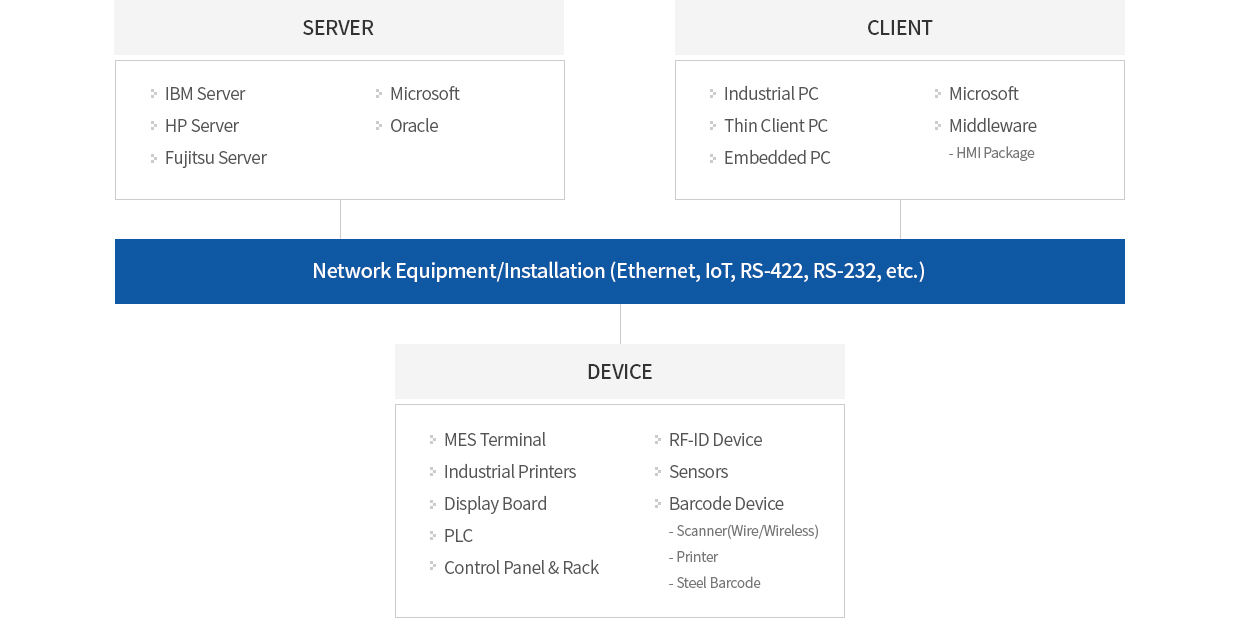

Equipment Supply & installation